Hot search keywords:

Company Overview

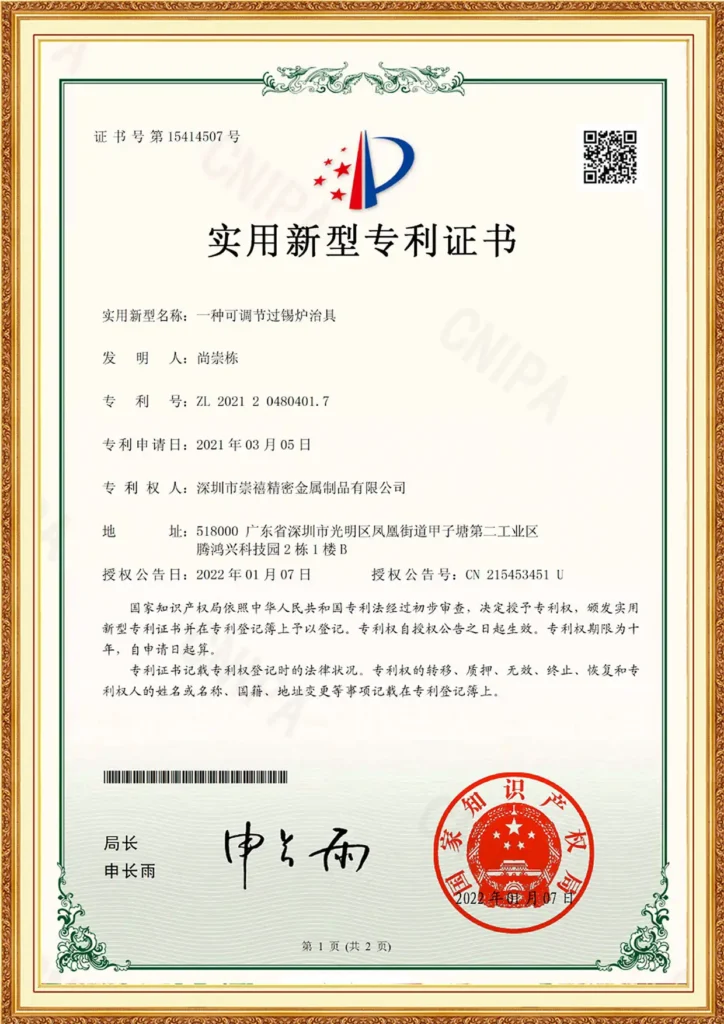

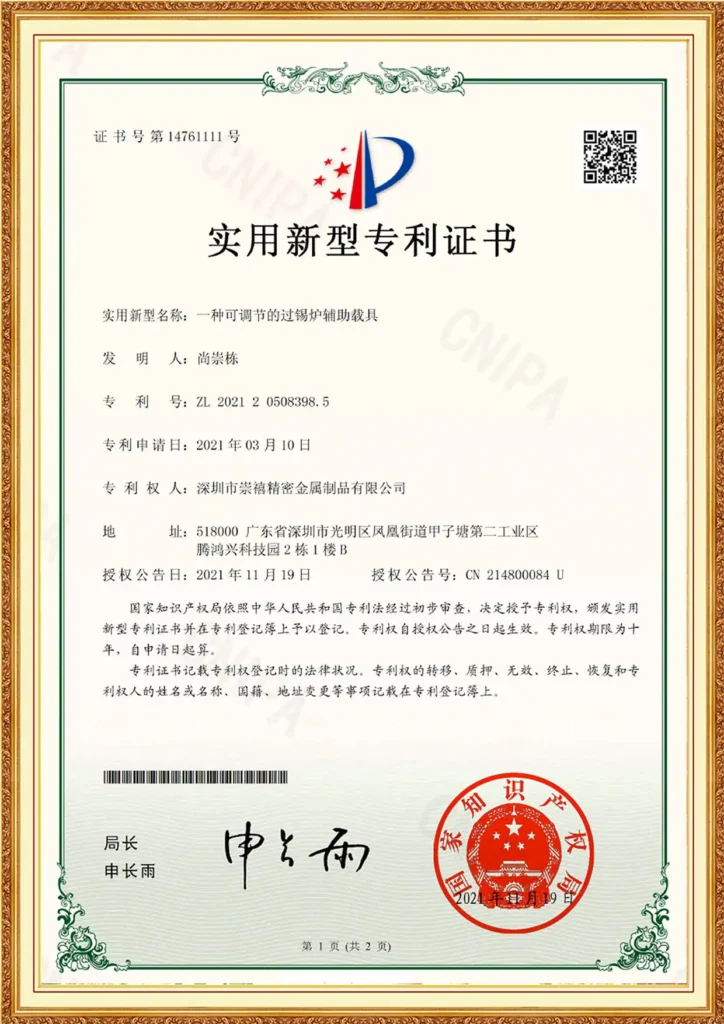

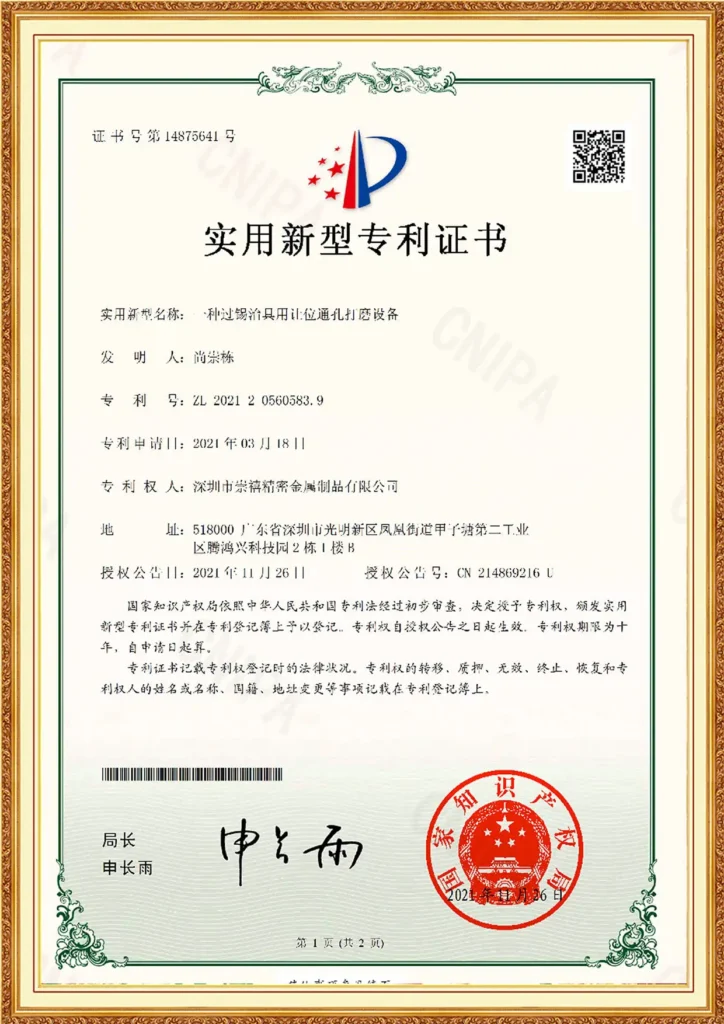

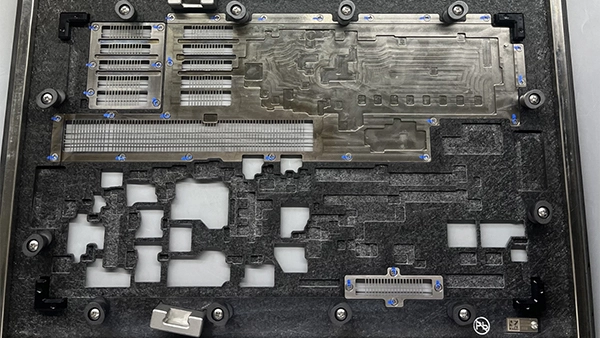

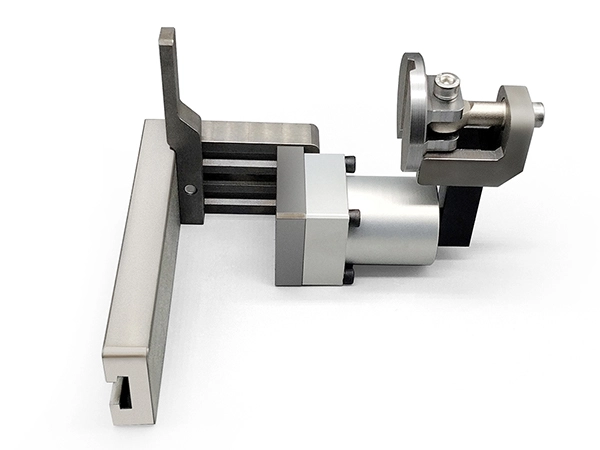

Since 2013, Shenzhen Chongxi Precision Metal Products Co., Ltd. has been dedicated to the customization of non-standard, high-precision hardware components and finished parts for clients worldwide.

Located in Guangming, Shenzhen, our 2000㎡ modern facility integrates design, R&D, manufacturing, and sales, ensuring one-stop precision solutions for industries such as electronics, automotive, machinery, and communication.

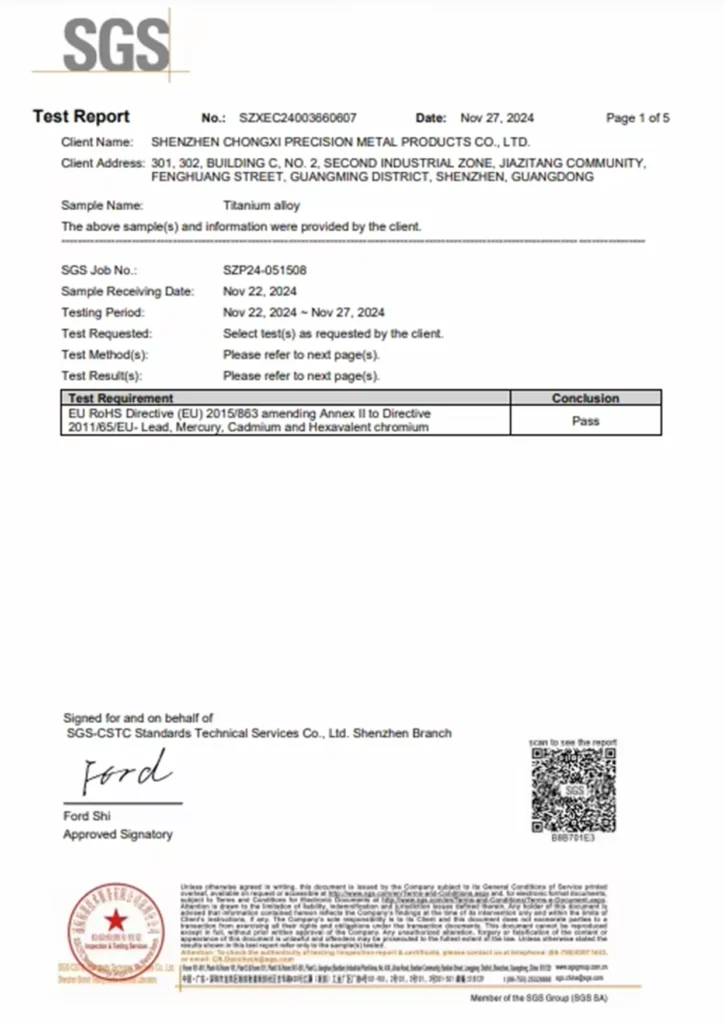

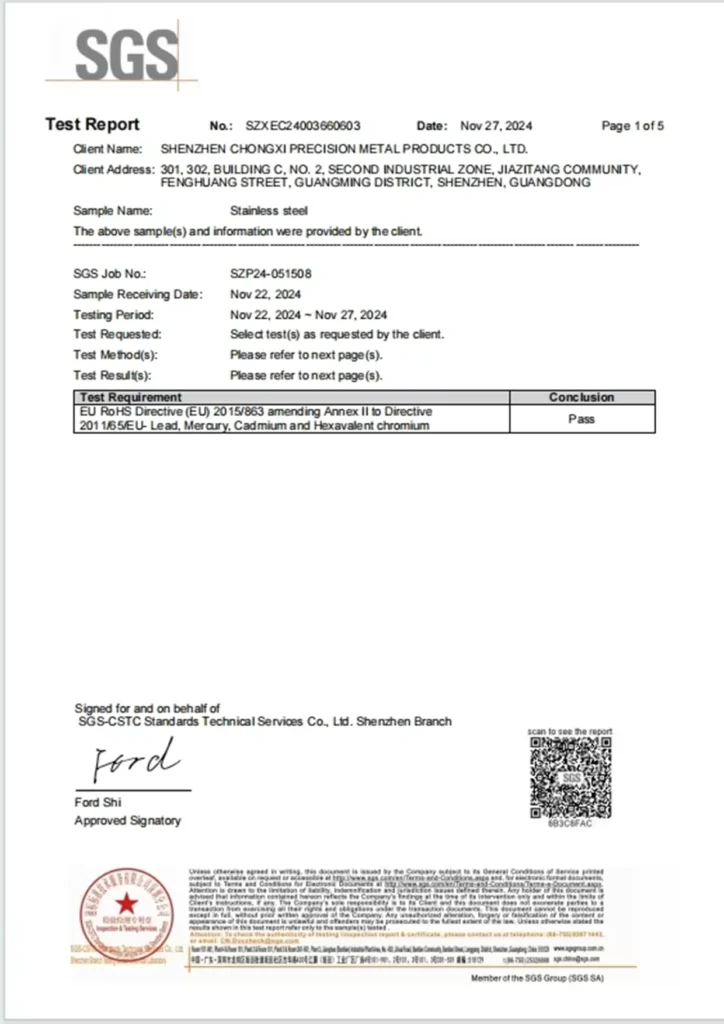

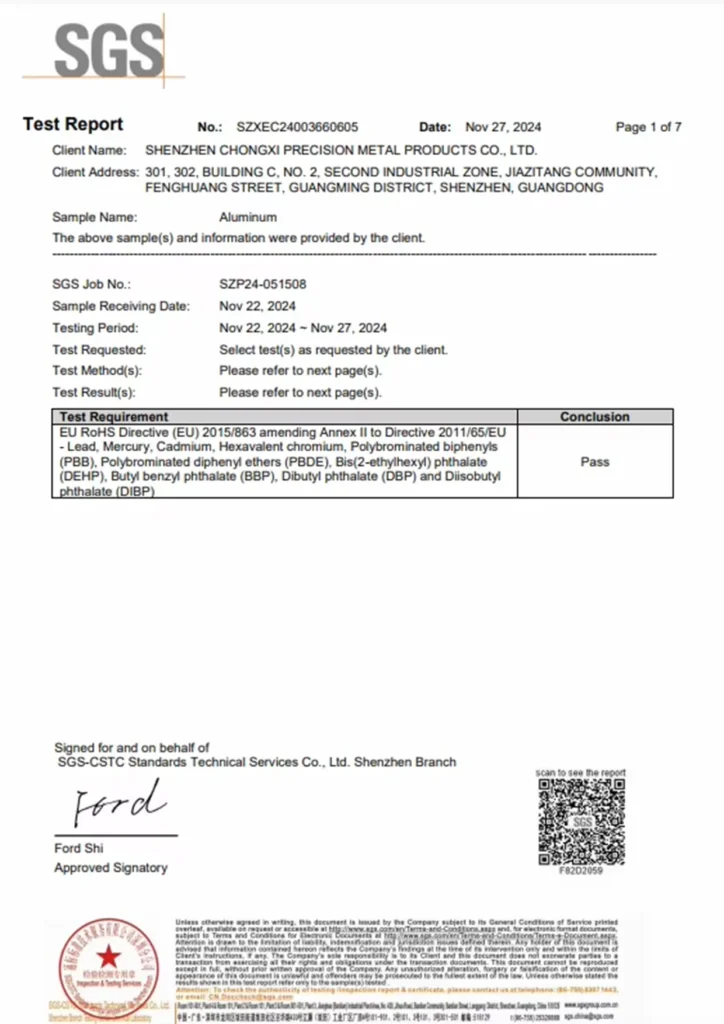

Certified with ISO9001 quality management system, Chongxi adheres to strict production standards and continuous innovation, delivering components that meet the highest international requirements. With independent import and export rights, we serve global customers with efficiency, professionalism, and integrity.

From Microns to the Future

We provide custom precision parts for electronics, automotive, medical, and aerospace industries.

Electronics

Automotive

Industrial

Automation

Medical

Aerospace

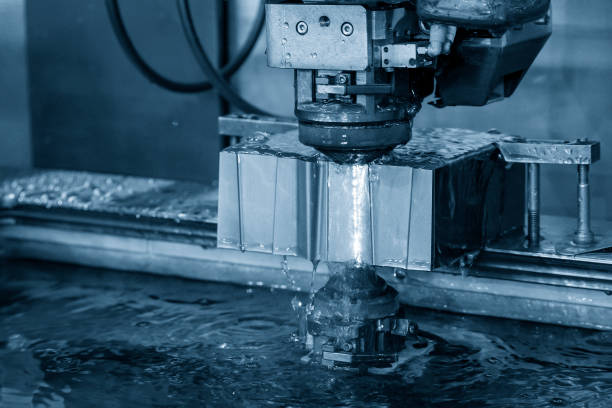

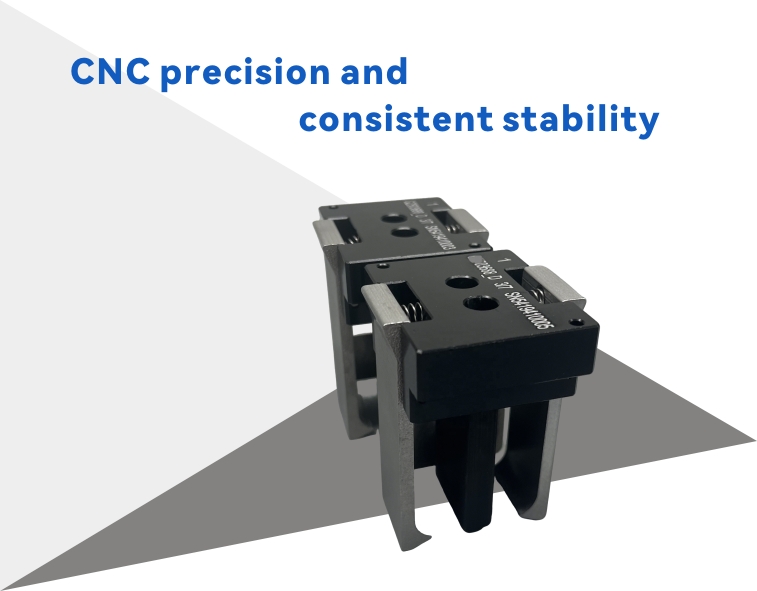

Precision Processing

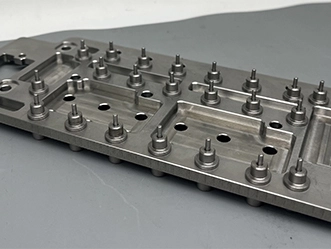

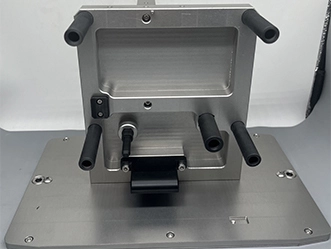

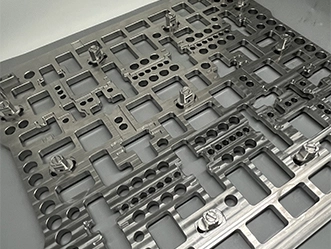

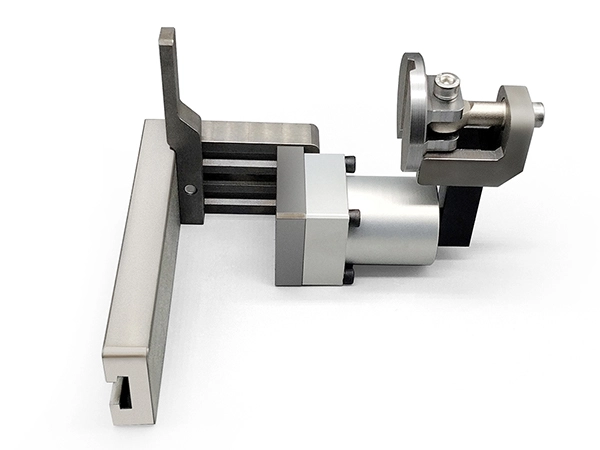

Multi-material CNC machining with ±0.01mm tolerances and a variety of surface treatments ensures both performance and aesthetics.

Technical Strength

Advanced equipment and specialized qualifications ensure end-to-end quality control, driving intelligent manufacturing upgrades.

Application Value

Customized solutions covering electronics, automotive, medical, aerospace, and other fields are helping to drive industry upgrades.

13 Years of Aluminum CNC Machining Experience

Chongxi focuses on precision manufacturing, fast delivery, and reliable quality.

High Precision & Consistency

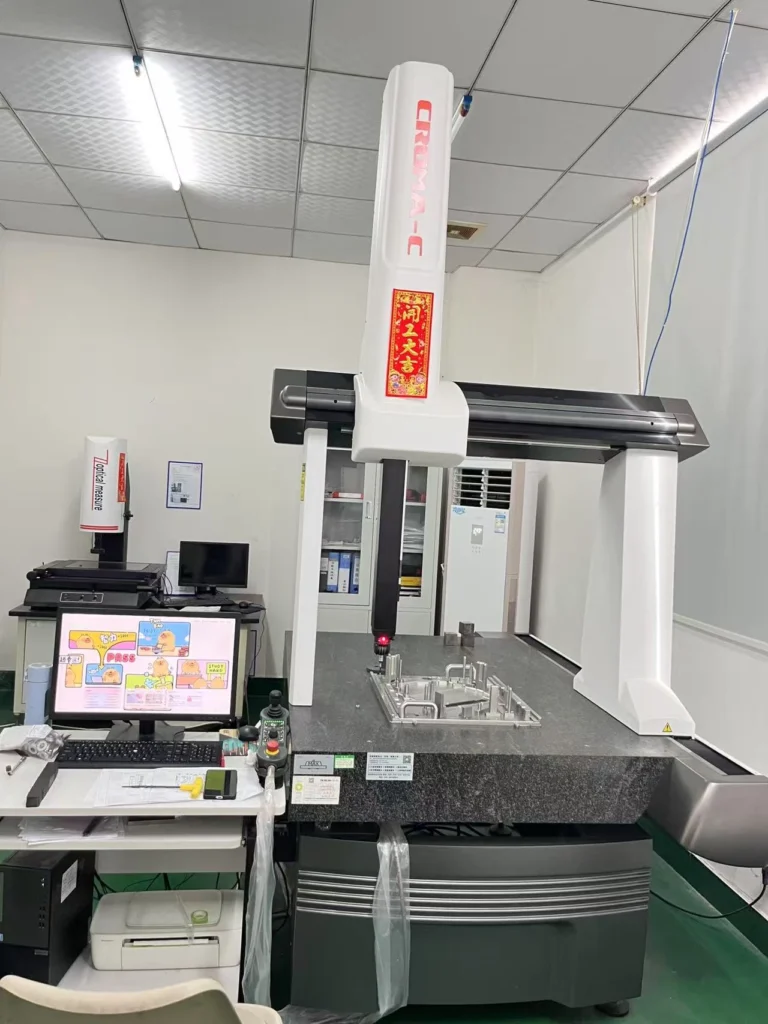

40 CNC machines and advanced inspection equipment ensure stable accuracy and quality.

Fast Delivery

7-day prototyping and 15-day mass production with smart programming and efficient processes.

High Yield Rate

Five-step quality inspection, with an appearance parts pass rate of up to 90%, minimizing rework.

Cost Optimization

Free process optimization reduces material waste and tool wear, maximizing your ROI.

Precision creates quality

Advanced equipment and strict quality control ensure that each part is of high precision and high reliability.

Comprehensive Manufacturing Strength for Reliable Partnership

From expert teams to strict quality control, we deliver with advanced processes, on-time production, and dependable service—ensuring high-quality results and long-term collaboration.

One-Stop Precision Manufacturing, Backed by Innovation & Quality

Fast & On-Time Delivery, Always

Your Trusted Partner for High-Precision Custom Hardware

High-Precision Production, Crafting Every Perfect Component

Every Step Under Strict Control, Quality Without Compromise

Comprehensive Service Solutions for Every Need

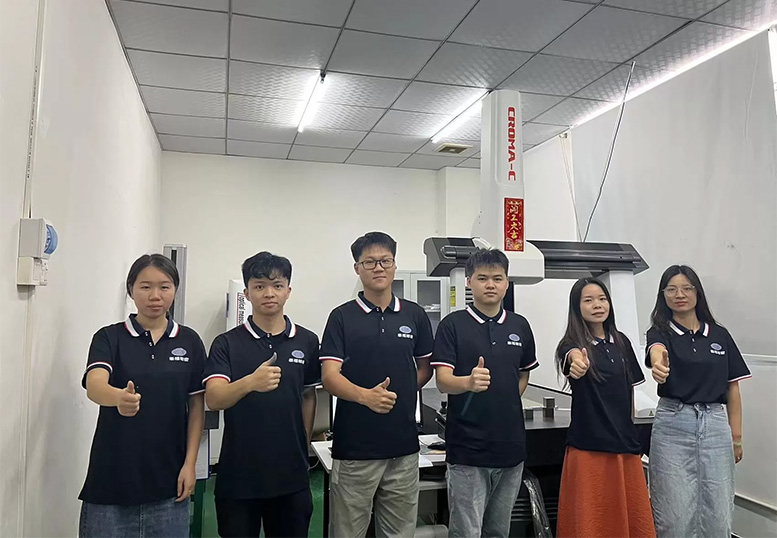

Professional Team

We control the whole process to ensure precision, reliability, and efficient custom solutions.

CNC Metrology Engineer

Process Engineer

CNC Programmer

Together, we innovate, collaborate, and move forward

Trusted by Leading Brands

One-Stop Precision Manufacturing

From concept to delivery — streamlined for speed, quality, and reliability

Requirement

Specs & material confirmation

Design & R&D

3D modeling & feasibility

Tooling

Custom molds & jigs

Three-dimensional measurement

High-precision cutting

Inspection

Size & quality checks

Support

Quick after-sales service

After-sales

On-time global shipping

Packaging

Secure pack & label

Assembly

Fit & function testing

Finishing

Deburring & surface work

Company News

Discover the latest stories and milestones from our journey

Chongxi Updates

The aerospace industry demands absolute perfection in 2026. Every component must meet extreme safety standards. Specifically, achieving a ±0.001” tolerance is a massive challenge. Traditional fabrication methods often fall short of this goal. However, precision is the backbone of flight safety. High-quality aerospace sheet metal processing ensures that every part fits perfectly. This guide reveals how […]

The medical industry demands absolute perfection in 2026. Specifically, bone screws require extreme dimensional accuracy. Even a tiny error can cause surgical failure. Therefore, achieving sub-micron precision is now a standard requirement. However, mastering this level of detail is very difficult. It requires specialized equipment and deep technical knowledge. High-quality precision medical machining ensures patient […]

In 2026, the demand for extreme accuracy is skyrocketing. Industries like aerospace and medical tech require incredible precision. Specifically, hitting a tolerance of +/- 0.001 mm is a massive challenge. This level of detail represents the pinnacle of modern manufacturing. However, achieving this consistency requires more than just good machines. You need a perfect blend of […]

Technical Encyclopedia

Frequently Asked Questions

Materials Suitable for CNC Machining

Metals Aluminum Alloys – 6061, 7075, 5052; lightweight, corrosion-resistant. Stainless Steel – 304, 316; excellent corrosion resistance. Carbon Steel – Strong and cost-effective. Titanium Alloys – Aerospace-grade strength and corrosion resistance. Copper & Brass – Conductive and easy to machine. Magnesium – Ultra-lightweight, good strength-to-weight ratio. Plastics POM (Delrin) – Low friction, high stiffness. PEEK […]

What Materials Can CNC Machines Process?

CNC machining is incredibly versatile and can handle a wide range of metals and plastics. Common Metals: Aluminum Alloys (e.g., 6061, 7075) – Lightweight, corrosion-resistant, excellent for aerospace and electronics. Stainless Steel (e.g., 304, 316) – Strong, corrosion-resistant, ideal for medical and food-grade applications. Titanium Alloys – High strength-to-weight ratio, commonly used in aerospace and […]

What is CNC Machining and Why is it Important?

CNC machining is a manufacturing process that uses pre-programmed computer instructions to control the movement of cutting tools and machinery. Unlike manual machining, where the operator guides each movement, CNC machines execute programmed commands with extreme precision—every cut, every depth, and every spindle speed is controlled down to fractions of a millimeter. The key advantages […]

What materials can be CNC machined?

Common CNC machining materials include: Metals: Aluminum, stainless steel, brass, copper, titanium, steel alloys Plastics: POM (Delrin), PEEK, ABS, PTFE, Nylon We help clients select the most suitable material based on application and cost-performance ratio.

What is CNC machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block (metal or plastic) to create precision parts.

- Looking for more options?

- Cnc Machining

- Milling machine

- Lathe machining

Founded in 2013, Chongxi Precision Metal Products Co., Ltd. specializes in high-precision, non-standard hardware components and finished products. Located in Guangming, Shenzhen, China, we offer comprehensive services from design and R&D to manufacturing and sales. With over 55 professionals and ISO 9001 certification, we guarantee high-quality products and on-time delivery, serving industries like consumer electronics, automotive, industrial control, and medical accessories.[See Details]